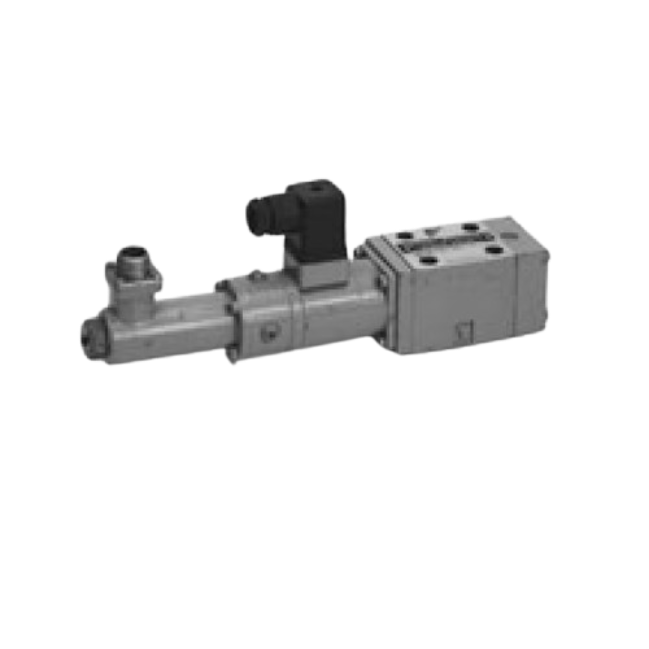

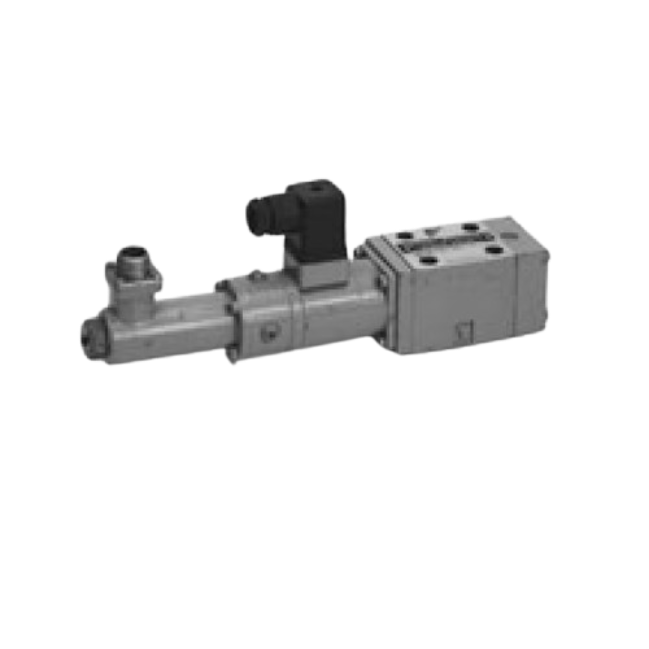

Achieves optimum control of minor feedback control type LEM* valves by detecting the spool position with a differential transformer. The constant current characteristics suppress the power supply voltage fluctuation, and the output current fluctuation due to temperature rise of the solenoid, to almost zero.