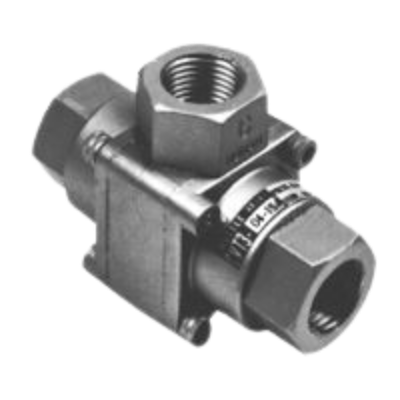

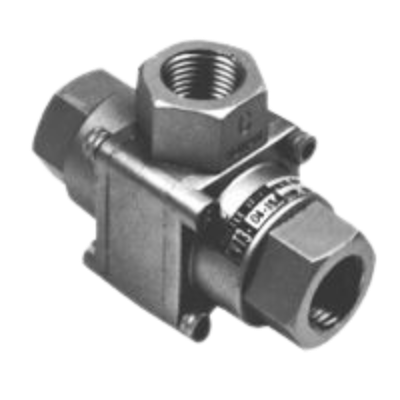

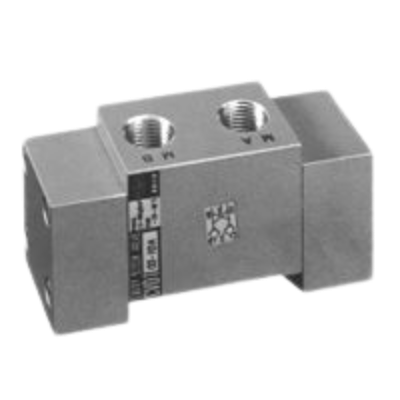

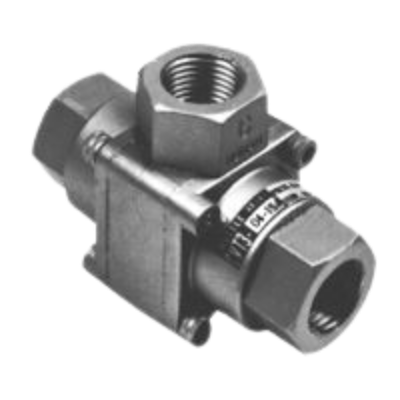

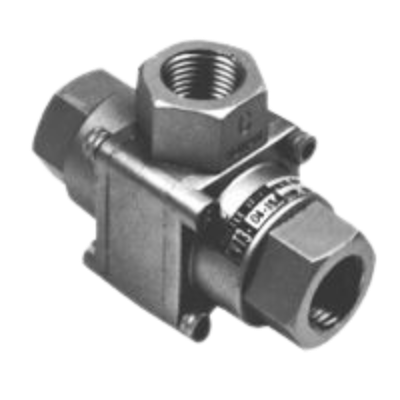

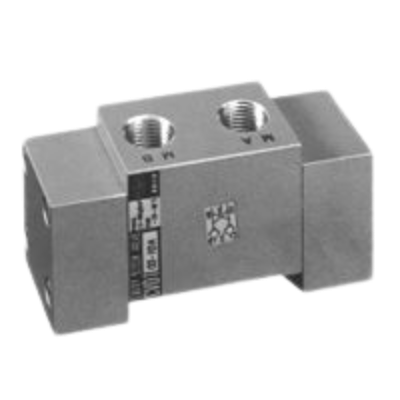

820-4395/-4397/-3184/-3186/-3188 Standard type(Port size:Rc3/8 , Rc1/2 , Rc3/4 , Rc1 , Rc1 1/4 , Rc1 1/2 , Rc2 , Rc2 1/2); 820-4396/-4398/-3185/-3187/-3189 Corrosion-resistant type(Port size:Rc1/4 , Rc3/8 , Rc1/2 , Rc3/4 , Rc1 , Rc1 1/4 , Rc1 1/2 , Rc2 , Rc2 1/2 )